Were Anastas and Warner the catalyst within the scientific community for the development of sustainable chemistry. Was in 1998 when they published the 12 principles of green chemistry, which preceded the publication in 2003 by Anastas and Zimmerman of the 12 principles of green chemical engineering. In those publications, it is brought to the attention of scientist and engineers the need for the development of a more sustainable scientific activity. We can list the 12 principles of sustainable chemistry as are listed in the green chemistry section of the American Chemical Society:

1. Prevention

It is better to prevent waste than to treat or clean up waste after it has been created.

2. Atom Economy

Synthetic methods should be designed to maximize the incorporation of all materials used in the process into the final product.

3. Less Hazardous Chemical Syntheses

Wherever practicable, synthetic methods should be designed to use and generate substances that possess little or no toxicity to human health and the environment.

4. Designing Safer Chemicals

Chemical products should be designed to affect their desired function while minimizing their toxicity.

5. Safer Solvents and Auxiliaries

The use of auxiliary substances (e.g., solvents, separation agents, etc.) should be made unnecessary wherever possible and innocuous when used.

6. Design for Energy Efficiency

Energy requirements of chemical processes should be recognised for their environmental and economic impacts and should be minimised. If possible, synthetic methods should be conducted at ambient temperature and pressure.

7. Use of Renewable Feedstocks

A raw material or feedstock should be renewable rather than depleting whenever technically and economically practicable.

8. Reduce Derivatives

Unnecessary derivatization (use of blocking groups, protection/ deprotection, temporary modification of physical/chemical processes) should be minimised or avoided, if possible, because such steps require additional reagents and can generate waste.

9. Catalysis

Catalytic reagents (as selective as possible) are superior to stoichiometric reagents.

10. Design for Degradation

Chemical products should be designed so that at the end of their function they break down into innocuous degradation products and do not persist in the environment.

11. Real-time analysis for Pollution Prevention

Analytical methodologies need to be further developed to allow for real-time, in-process monitoring and control prior to the formation of hazardous substances.

12. Inherently Safer Chemistry for Accident Prevention

Substances and the form of a substance used in a chemical process should be chosen to minimize the potential for chemical accidents, including releases, explosions, and fires.

Taking a close look at the 12 principles, we can use strategies that help to follow them, by using better solvents, energy sources that can faster the chemical process, obtaining better catalyst or obtaining new sensor that can drive to a fast recognition of toxic analytes. Let’s dig a little deeper into some of them!

Solvents

Solvents play an essential role in the reactions. They are used most of the times in more quantity than any reactive species and are one of the most important waste generators. Solvents like hexane or toluene are petroleum derivate, other can be volatile like acetone or flammable like diethyl ether, making dangerous the work with them. The easy dispersion, accumulation and toxicity of chlorinated solvents in the environment is an important source of contamination. A purely solvent-based process, avoiding mixing of solvents, can be a strategy to reduce the waste if we are able, for example, to recover and use it again. However, the use of preferentially water as well as new solvents can also have a positive impact in the environment as in the laboratory results.

Water has several advantages. It is not dangerous, not toxic, cheap and non-flammable. It allows to work at moderate temperature conditions (0-100 ºC), but also in near critical conditions (near-critical water (NCW), 150-350 ºC, 4-200 bar) or supercritical conditions (supercritical water (SCW), >374 ºC, >221 bar), in which properties as density or polarity are strongly modified.

However, there are few organic compounds soluble in water, what makes that new solvents must be developed in order to improve the “classic” ones.

Those new solvents can include ionic liquids, perfluorinated compounds or supercritical fluids. All of them has advantages and drawback, showing that, nowadays, the perfect solvent does not exist, just the most convenient to the chemical process.

Catalyst

A catalyst is a compound that affects the reaction rate, speeding up or slowing down (also called inhibitors), but that does not appear in the stoichiometry of the reaction. The catalyst is not consumed during the reaction process and must be regenerated, so it can be reused in the reaction more than once.

We can classify the catalyst in homogeneous and heterogeneous.

Homogeneous catalyst

The catalyst as well as the reagents are in the same phase (usually in dissolution). They can be acids, bases, or Lewis acids like AlCl3, TiCl4 or BF3. The use of metals like Pd, Pt, Fe, Ni, Co or Cu with d orbitals partially occupied have also a widespread use. They have several advantages like a more homogeneous distribution within the solution, or the possibility to use a more specific catalyst.

One of the main problems is the separation of the catalyst and the reaction products with the consequent waste generation.

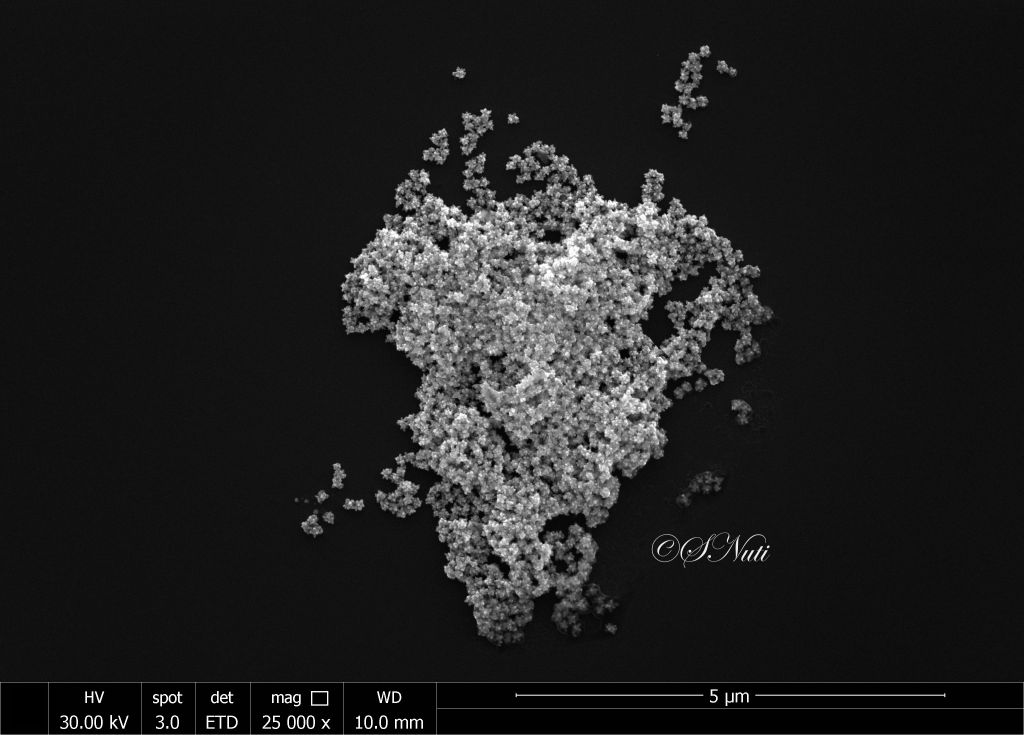

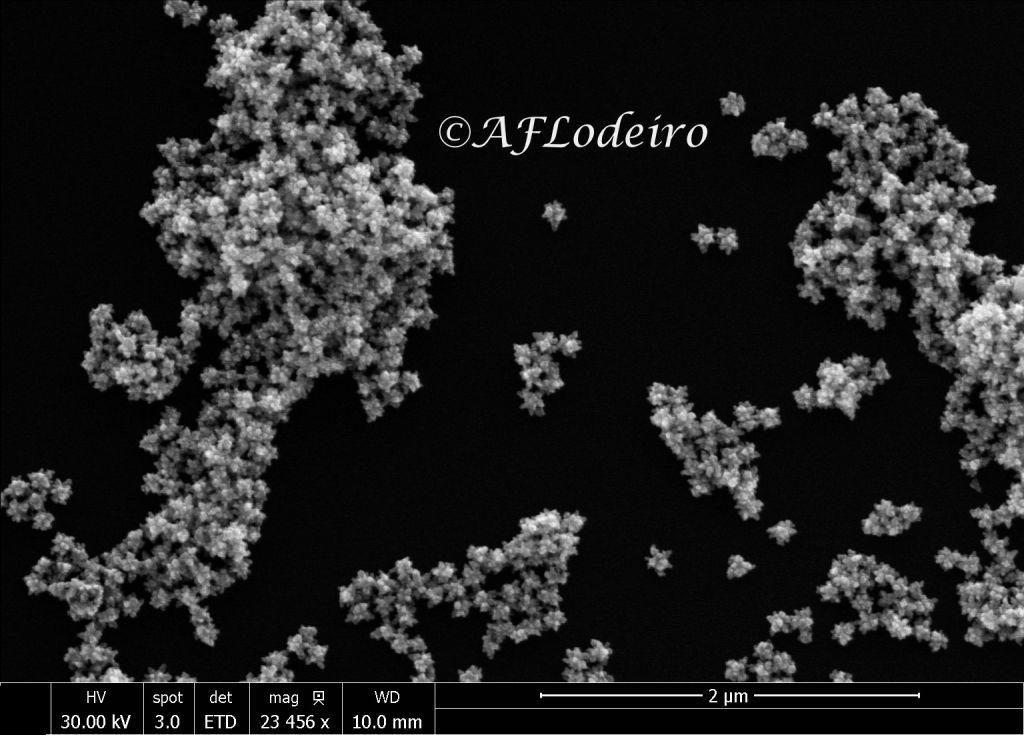

Heterogeneous catalyst

In this case, the catalyst and the reagents are in different phases (for example the catalyst as a solid and the reagents as a liquid).

Heterogeneous catalyst presents some advantages, such as an easy way to separate the products and the catalyst, or the thermally and chemically stable materials used. Zeolites are an important type of materials used in several catalytic processes.

The reaction conditions used to be more severe than with homogeneous catalyst.

Ultrasounds and Microwaves.

The use of ultrasounds and microwaves in the synthesis procedure can lead to improved methodologies, with the following lower use of time and energy in the process, making them more suitable for industrial scale.

Ultrasounds

Ultrasounds are acoustic waves with more than 20 KHz, until the 10 MHz. The use of high frequency and intensity waves can present several advantages in the synthesis of new products, like faster conversions, mild reaction conditions or lowering the number of steps in a procedure. When the ultrasounds are applied in a liquid, they lead to the formation of microbubbles that collapse and give arise to temperatures in the order of 4.000-6.000 K and pressures of 1.000 – 2.000 bar. They have been used extensively in analytical chemistry. Ultrasounds can be considered as a clean source of energy, with no toxicity and with cheap equipment.

Microwaves

Microwaves are electromagnetic waves, with a wavelength range between 1 cm and 1 m. It corresponds to frequencies between 300 and 3.000 MHz. It is possible to introduce thermal energy in chemical reactions with the use of microwaves. It has several advantages like lowering the time of heating, present different temperatures in the mixture or a selective heating.

Electrochemistry and Photochemistry

Electrochemistry and photochemistry are called to have an important place in the development of greener process, giving rise to new products and methodologies with fewer wastes and use of energy than the usual procedures.

Electrochemistry

When a chemical process causes electrons to move, they give place to the oxidation-reduction (redox) reactions. If we do this process placing different electrodes connected with a saline environmental in a solvent, we are talking about an electrochemical reactor.

The electrochemical process offers several advantages like mild and easy control of the conditions, almost no risk process and high atom efficiency. Once the electrodes are usually in a dissolution, they can be considered as a heterogeneous catalyst. They are used to avoid the addition of oxidants or reducers that can lead to sources of contamination.

The main inconvenient can be the high cost of electrochemical reactors for laboratory scale or the high energy consumption in an industrial application.

Photochemistry

Taking advantage of the use of light, ultraviolet, visible or near infrared, to produce new chemical products, is a growing field of research. With the reasonable use of light and under certain conditions, it is possible to obtain new results in the chemical synthesis as well as produce or induce interesting properties in some materials. Photovoltaics, the ability to convert sunlight into electricity, can be improved with the use of nanostructures and give a new option for solar cell devices.

The main advantages of the photochemical process are the possibility to reduce the number of reactive, the use of mild temperatures or being a selective process. Some molecule or materials interact at an electronic level with the light, and this can lead to specific reactions.

The photochemical process still presents several drawbacks, among them, the low absorption of the radiation or the higher price of apply the photochemistry to obtain the same product in comparison to another methodology.

Analytical methodologies

The development of new analytical methodologies is an essential field of research. The identification and quantification of analytes in a fast and reliable way is useful in several areas. The quick identification of toxic analytes, or precursors of toxic analytes, can lead to prevention or an implementation of a necessary action to minimise the adverse effects derived from their presence. For this reason, it is essential to develop new and fast strategies that can avoid the use of expensive equipment. Colourimetric methodologies that can give a response to a particular analyte with colour changes, or related fluorescence process (enhancement or quenching), can be fundamental in an in-situ analysis.

Toxicity

As we saw in the previous sections, it is highly vital to take into consideration the toxicity and toxicology effects, not only in the synthesis and manufacturing but also in the applications.

Metals like mercury where used in the past in several fields, as an antibacterial agent, to control plant diseases in the agriculture or for the manufacturing of hats. The ingestion or exposure to its vapours can lead to memory loss or hyperactivity, among others. Also, the organic mercury compounds, like methylmercury, can cause death. In this sense, the toxicity studies are highly essential to avoid the use of potentially toxic materials.

Likewise, is well known that the toxicity of some substances depends on the dose, and when some substances may be innocuous, beneficial or even necessary for life at low doses, at high doses may be harmful. A notable case of toxicity can be seen in the chemotherapy compounds. The use of different drugs against cancer disease can have a harmful effect on the healthy parts of the body. An application or combination of new treatments that will eliminate or reduce the use of these drugs without compromising the beneficial effect would be preferred.

You must be logged in to post a comment.